Septic tanks and separators

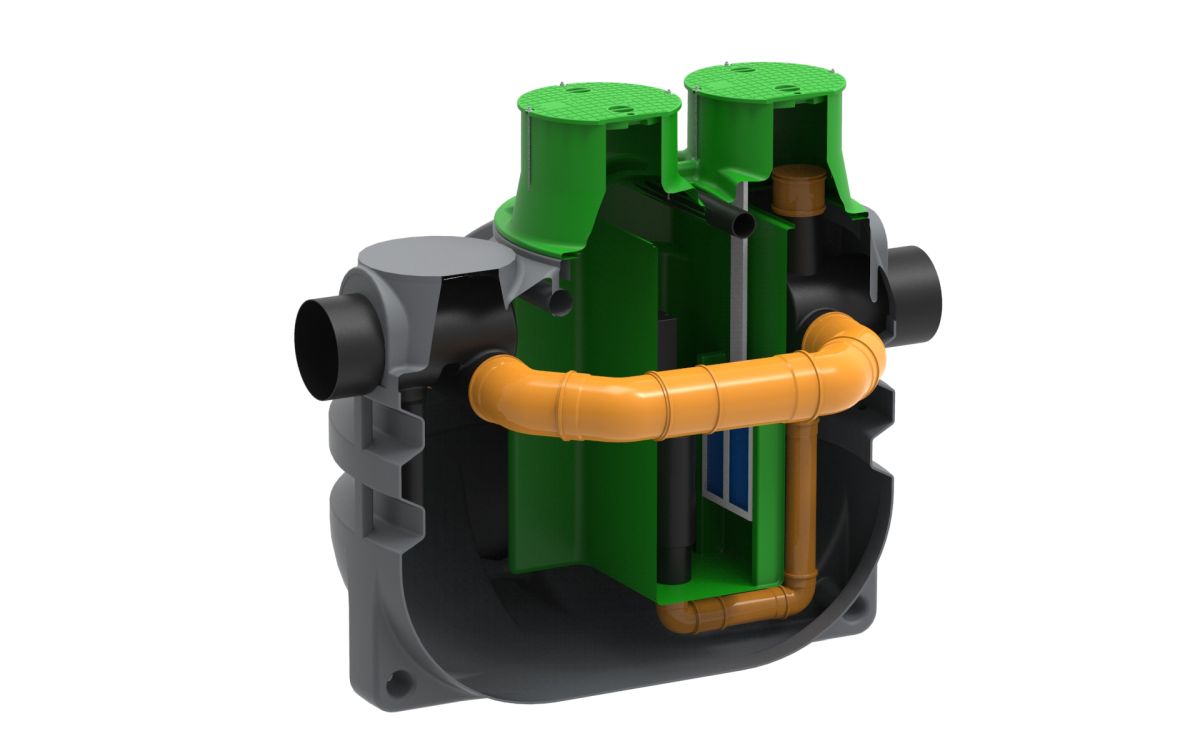

Hydrocarbon separators are design according to the EN858 and DIN 1999-10 standards.

The hydrocarbon separators offered by Teraplast are made from polyethylene through the process called “rotomoulding” or rotational moulding. This is a process that allows the individual rotation of the model when the polyethylene powder is introduced into two directions.

Through this process can be obtained large size products with different shapes.

Hydrocarbon and oil separators are necessary where there are light liquid leakages. These appear usually at:

- gas stations;

- car wash;

- car repair shops;

- parking.

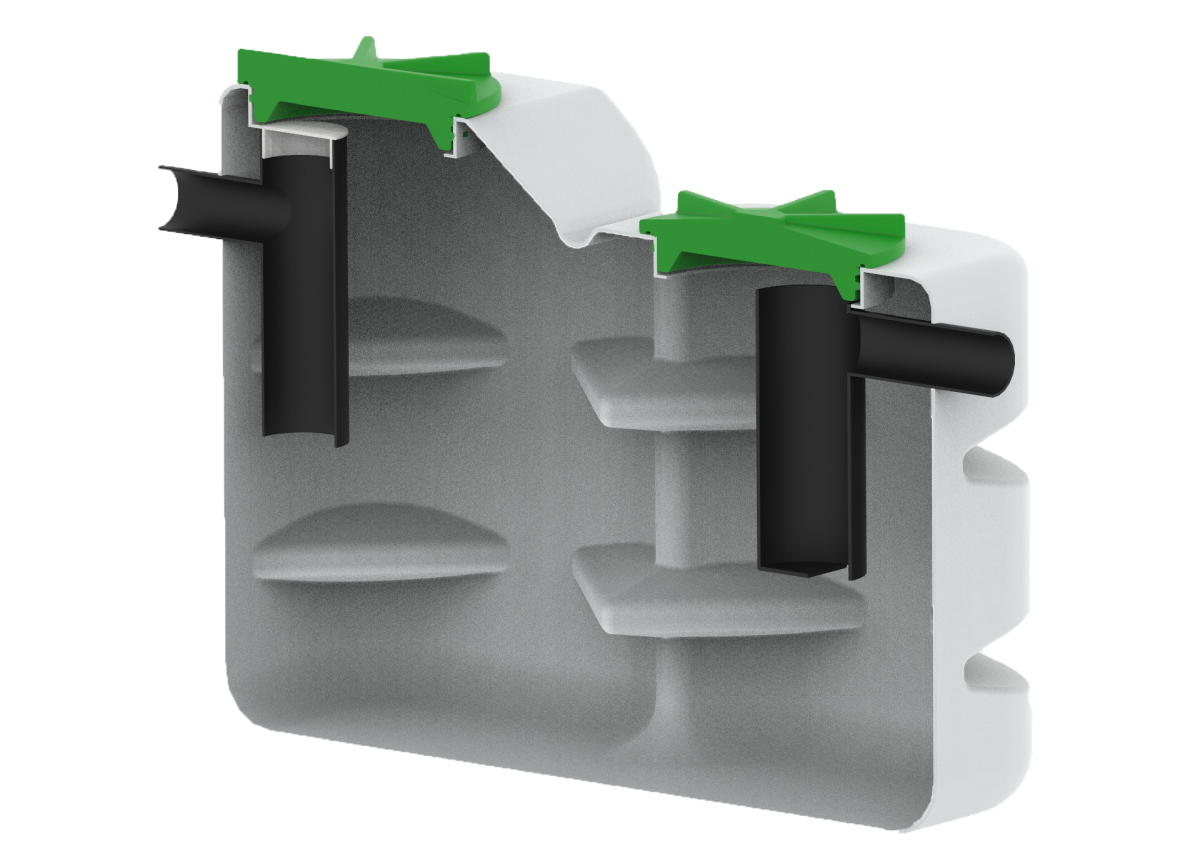

Description of the grease separator range

In order to prevent the deterioration of sewage pipes and water cleaning stations, in the activities that produce wastewaters that contain grease, the grease separators need to be installed in accordance with the EN1825 and DIN 4040-100 standards. These reduce incidents such as kitchen clogged pipes, improve septic tank performance, and prevent the contamination of small water cleaning stations.

The grease separators offered by Teraplast are made from polyethylene. They are extremely durable, with reduced waste and are resistant to different chemicals used in the kitchen.

The grease separator needs to be installed near a contamination source, inside or ouside the building.

The grease separator located underground, needs to be near the building, in areas where strong and aggressive smells will not be a problem and in the area where it is possible the access using the collecting hose of the vacuum truck.

The level of the intake connection needs to be below the freezing level. The grease separator needs to be opened in order to be emptied.